Industrial - Commercial

Industrial - Commercial  Electrical

Contractor

Electrical

Contractor

PDQ Electric Corp

NJ, PA, DE, MD, NY, CT, DC, MA, RI

|

PDQIE - PDQ Industrial ElectricAuxillary Power, Backup Generator, Generator

Sizing Amperage Chart, Backup Plan

|

| Airman | Atlas-Copco | Atlas-Copco |

| Avtron | Armstrong | Baldor |

| Briggs and Stratton | Caterpillar | Chicago Pneumatic |

| Cooper Crouse-Hinds |

Cummins |

Cutler Hammer |

| Detroit Diesel | Generac | General Electric |

| Katolight | Kirloskar Bliss | Kohler Power Systems |

| Kubota | L.S.A. | Lister Petter |

| Mitsubishi | MQ Power | Onan |

| Perkins | Pramac | Ricardo |

| Simplex | Stamford | Taylor Power Systems |

| Wacker | Windsor | Yanmar |

Diesel fuel is an excellent fuel to operate electric generators with. Diesel has historically been less expensive than gasoline (although that may be changing) and is readily available almost anywhere. Diesel Fuel, ( when stored correctly) is very stable, has good shelf-life, and is usually not affected by the elements or mechanical disruptions that cause most residential power outages. Another major advantage to diesel is the lower operating temperature of the diesel engine itself. Diesel fuel enables combustion at a lower temperature and thus the entire engine does not have to endure the effects of a high temperature operating environment, this adds significantly to the overall expected life of the engine and greatly reduces the maintenance cost of engine repair and-or rebuilds (which are to be expected at some point).

What is Load Management?

The technology in today’s home standby generators is downright amazing. Smaller units doing the same job where larger generators were once required. A big thanks to load management technology. Most all the major manufactures have some form of load management design marketed under different names with subtle differences specific to each manufacture. ACCM (Air Conditioning Control Module) from Briggs & Stratton. DLM (Digital Load Module) from Generac Power Systems and there are also load shedding devices (load shedding device = load manager) from other manufactures that can be added to a home standby system that doesn’t have load management technology.

These load management systems are designed to let you back up more circuits than the generator may be rated to handle by not allowing the largest loads (which are usually the air conditioners) to demand power from the generator at the same time. This does not mean that if a 12-14kW unit can now handle two 3 ton air conditioners then it must be alright to handle one larger air conditioner. If you have this concern just take a moment to check the LRA amp rating of your air conditioner. The LRA (Locked Rotor Amp) and is the air conditioner manufactures listing for the total amperage it takes to turn on the air conditioner. The LRA rating is listed on a data plate that is on condenser for the air conditioner.

Standby manufactures rarely publish the surge capacity of these generators, mostly because you should not rely on any available surge for continuous duty. The LRA should be below the surge amps of the generator, and not all air conditioners are the same, you need to check the LRA.

Using a smaller generator today over what might have been the requirement years ago is money saving, fuel saving and smart. Automatic systems that practically think for themselves and can provide peace of mind and your property is protected whether you are there or not.

Call PDQIE for a Review of Your Generator Load Demands (877) PDQ-4-FIX

PDQIE will supply and install an Automatic-Standby Back-up Generator for those unfortunate times when Electrical Service is disrupted. We can also integrate an Automatic Transfer Switch which will automatically start your Generator in the event of a utility power outage.

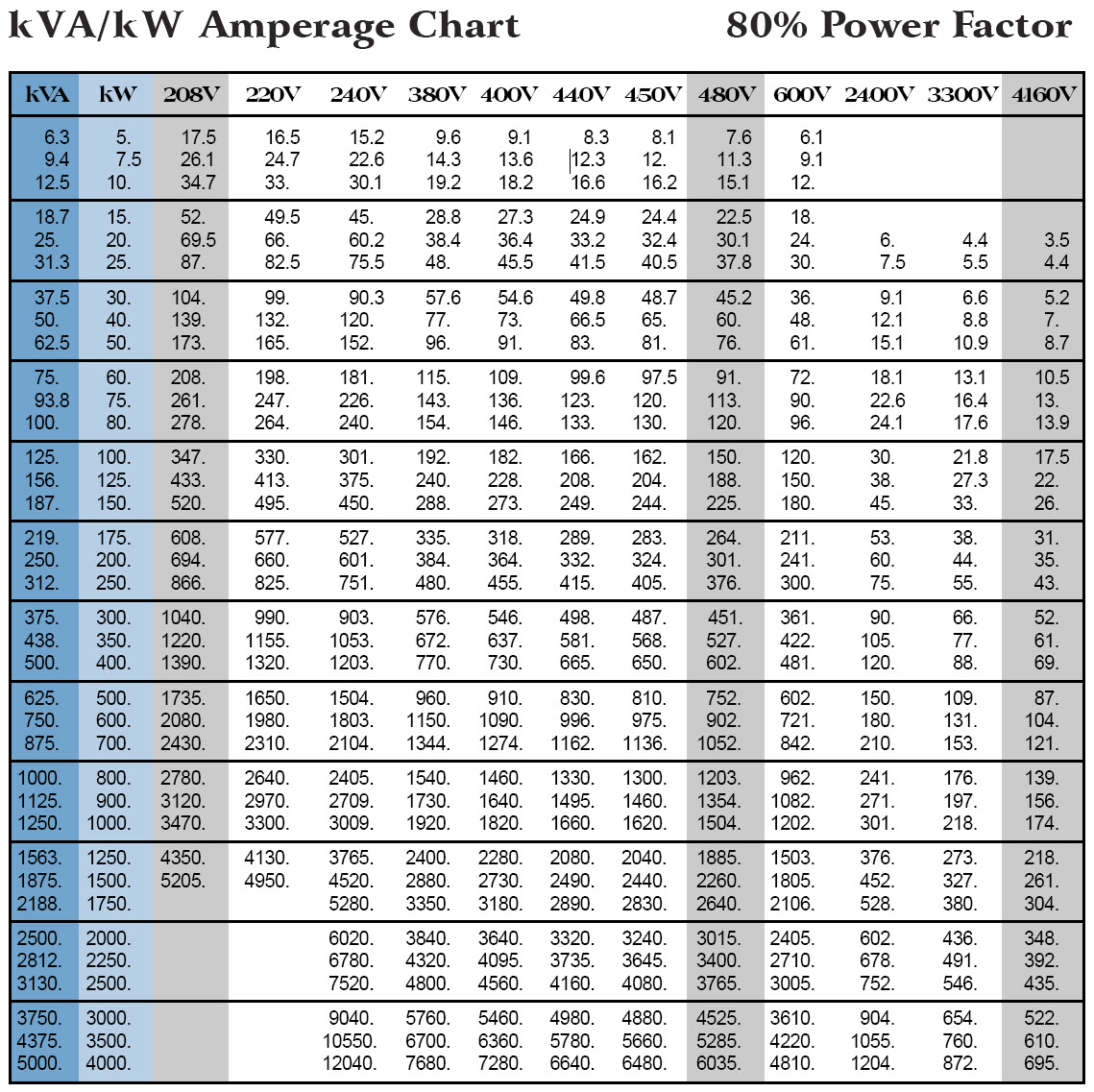

Generator Sizing Amperage Chart 80% Power Factor

A Backup Plan

Emergency Power Supply System (EPSS)

EPSSs are designed to be the reliable backup when electric utility power is lost. Considerable cost is invested on a typical EPSS installation to provide power for life safety lighting and critical power in buildings. There are also installations in many facilities — where entire buildings are served by emergency power — that can cost hundreds, thousands, or even millions of dollars to supply emergency power.

In many instances, once the emergency system components are installed and commissioned, they’re not tested properly or as frequently as they should be. Generators may be routinely started and allowed to run for short periods of time, but load is not placed on the generator set through switching of the building transfer switches because of the impact to building equipment and occupants. Other times, transfer switches and other electrical components that are part of the system are not exercised, which, by the way, is a Code violation.

NFPA 110 requires you to perform routine tasks and provide documentation to ensure system reliability.

NFPA 110 BACKGROUND

NFPA 110

is the “Standard for Emergency and Standby Power Systems.” It defines an EPSS as, “A complete functioning source of

electric (emergency) power of the required capacity and quality, coupled to a system of conductors, disconnecting

means and overcurrent protective devices, transfer switches, and all control, supervisory, and support devices up

to and including the load terminals of the transfer equipment needed for the system to operate as a safe and

reliable source of power.”

In existence since 1976, the NFPA 110 Committee has focused on issues that occurred after the New York City blackout on July 13, 1997. This includes addressing the demand for guidelines for the assembly, installation, and performance of the electrical power systems supplying critical and essential needs during primary power source outages and establishing necessary equipment requirements to achieve a suitable and reliable on-site auxiliary electrical power source.

Formally adopted in 1985, the NFPA 110 document created the framework for prototype testing and maintenance requirements. Since then, additional testing requirements have been added to include installation and operational maintenance as well as testing beyond the generator — transfer switch(es), batteries, and breakers serving the electric utility and emergency power supplies are now required to be tested periodically to conform to the latest edition of NFPA 110, which has three categories for classifying an EPSS (EPSS Classification).

REQUIREMENTS

Section 8.3 of the 2005 Edition of NFPA 110 requires maintenance and operational testing to be performed “to ensure to a reasonable degree that the system is capable of supplying service within the time specified for the type and for the time specified for the class.” It describes the method for developing a maintenance and testing program as well as recordkeeping of EPSS components.

Section 8.4.1 states, “EPSSs, including all appurtenant components, shall be inspected weekly and exercised under load at least monthly.” Section 8.4 as a whole goes into detail about testing procedures and requirements for specific components (click here to see Table); however, the monthly load requirement bears the most impact on a facility.

REALITY CHECK

What happens

when you transfer loads served by the EPSS? There is a potential for many challenges posed by a power interruption

to occur during a normal open transition transfer. Although the loss of power can be merely a second or two during

the transfer from the normal to emergency source, the building mechanical systems and equipment can be

significantly affected.

There are many potential building system issues that can arise during transfer between the building normal and emergency power supplies. When certain systems/components are served by an EPSS, problems and solutions may include the following:

FIRE ALARM SYSTEM

Many fire alarm systems have latching troubles that require a reset, such as when power supplies (supplemental

notification appliance circuit panels) lose the normal power source or are switched at the automatic transfer

switch (ATS). You can mitigate this situation through some minor fire alarm panel reprogramming. There can also be

problems with voltage transients that occur during ATS switching. Installation of in-line surge suppressors will

help mitigate these issues.

BUILDING AUTOMATION SYSTEM

(BAS)

There are potential issues with power supplies that fail on BAS panels, causing them to

lose their program and go into default mode when the ATS switches. This can be mitigated through the implementation

of a regular preventive maintenance program for battery checking and replacement. In addition, delays during power

switching to equipment connected to the BAS can have detrimental effects in the building coordination with damper

and HVAC system interlocks, pumps and motorized valve operation, etc., especially when not all components are

connected to the same source of power. For example, dampers may close if they sense a loss of power, but a fan

could continue to run at full speed, potentially causing a hazardous scenario and damage to the system.

VARIABLE-FREQUENCY DRIVES

(VFDS)

Tied to the BAS, many VFDs will need to be programmed to “ride through” or catch the

equipment they serve “on the fly” to prevent a complete shutdown and restart upon a loss of power or ATS switching.

One example of where this is critical is where the VFD serves fume hood exhausts, and loss of negative pressure can

pose a safety or health hazard to building occupants as it could allow toxic gas to be released into a room.

Another situation could be an operating room where a change in room pressure could introduce contaminants into the

space.

RESEARCH EQUIPMENT

There is

a potential impact on research areas that are served by emergency power. Running extended periods on the generator

could result in damage to sensitive equipment due to potential voltage fluctuations under varying load conditions.

Because loss of data and/or research can be devastating, installing voltage regulation equipment can help reduce

your risks.

ULTRALOW/REFRIGERATION

EQUIPMENT

Some equipment of this type requires a manual reset of a local alarm or even the

equipment itself upon any loss of power.

GAS CABINETS

There are

interlocks and safeties installed on many gas cabinets to reduce or eliminate a safety risk. Loss of power, even

for a few seconds, can lock gas cabinets out and disconnect power to any equipment being used, costing downtime and

loss of revenue for the time the monthly EPSS testing occurs.

COMPUTER-COMMUNICATIONS

Computer servers are often connected to the EPSS in

today’s technology-driven society to allow for research and voice over IP to continue to be maintained. If an

uninterruptible power supply (UPS) is not installed upstream of the server equipment, it will experience a hard

reset upon the ATS switching. This is important to note, because buildings today are advanced — and losing

communications can impact facility services.

EPSS COMPONENTS

There is a

potential for equipment mechanical failure on older components (particularly ATS) with regular exercising. Routine

switching can greatly reduce life expectancy of equipment that is greater than 20 yr old.

MINIMIZING EPSS TESTING

IMPACT

Approaches to mitigating the impact on your facility range from specific to broad. The

implementation depends largely on the extent of work required to address the particular needs of your

facility.

For large facilities with intertwined systems, there are two widely used approaches for entire single-point EPSS integration. The first is UPS and flywheel technology, which uses specific equipment to fill the time gap between source switching. When a UPS option is selected, power quality can also be improved by using a double-conversion online interactive-style unit. Flywheel technology uses inertia to provide a mechanical (kinetic) energy storage source for a very short period of time. Both of these options are expensive, take up floor space, and require floor loading consideration — and require their own routine maintenance. However, they do adequately address switching problems and are well suited for new installation and retrofit applications where space is available.

The second option, using a closed transition ATS, synchronizes and momentarily (<50 msec) parallels the electric utility and generator sources. Installing this equipment at the ATS or immediately downstream (load side) offers a one-stop installation. This is a fairly expensive option requiring engineering calculations to be performed to ensure the electrical system fault currents are considered. It does not, however, have the same routine maintenance a UPS or flywheel requires. This type of approach is best suited for new construction but can be used in renovations.

DOLLARS AND SENSE

Equipment

to reduce the effect of ATS switching can be expensive to purchase and install — not to mention costly to maintain.

An overall assessment of each facility and life-cycle cost analyses will assist in determining the best approach to

resolving switching issues.

It should be noted that operational maintenance and testing can bear even greater costs over the long term than addressing the switching of ATS. Required monthly testing will cost both in used fuel and personnel time. For example, a 200kW diesel generator loaded 50% and tested for 30 min. will consume approximately 10 gal of fuel per month. In addition, personnel policy may require that the EPSS be monitored during the duration of the test and documentation of the EPSS be performed, which may take an hour per month. While this may not seem significant for a single building or facility, in a university or other type of large campus-style facility (where there may be as many as 100 generators powering academic buildings, research buildings, office buildings, and residence halls), the costs for NFPA 110 compliance can be staggering.

BENEFITS OF REGULAR EPSS

TESTING

Monthly testing of the EPSS and placing load on the generator set through ATS switching

will burn more fuel, reducing the possibility of microbe issues in diesel tanks and wetstacking and slobber in

diesel generators. It will also allow for load trending and provide information on the system capacity for any

future additions or modifications.

Overall, routine EPSS testing and proper preventive maintenance will allow you to be better prepared for catastrophic events, natural disasters, and rolling blackouts. In addition, Code required testing of EPSS should be considered during design to resolve recurring and potentially costly disruptions to building systems and occupants.

|

Model # |

B&S Generator Systems Description | |

| 040315GEA |

7 kW |

Generator System by GE with 50A, 10 Circuit Transfer Switch |

| 040323GE |

11 kW |

Generator System by GE with Symphony II™ Whole House 200A |

| 040324GE |

13 kW |

Generator System by GE with Symphony II™ Whole House 200A |

| 040330GE |

15 kW |

Generator System by GE with Symphony II™ Whole House 200A |

| 040331GE |

20 kW |

Generator System by GE with Symphony II™ Whole House 200A |

| 076034 |

30 kW |

Generator System by GE (Transfer Switch Offered Separately) |

| 076035 |

48 kW |

Generator System by GE with 50A, 10 Circuit Transfer Switch |

|

Model # |

B&S Transfer Switch Bundles and Modules Description | |

| 040331GE & 071057 |

20 kW |

Generator System by GE with Dual 200A/Split 400A Transfer Switch |

| 076034 & 071057 |

30 kW |

Generator System by GE with Dual 200A/Split 400A Transfer Switch |

| 076035 & 071057 |

48 kW |

Generator System by GE with Dual 200A/Split 400A Transfer Switch |

| 071054 | Symphony™ II Whole House 200A Transfer Switch for Liquid Cooled Units | |

| 071051 | Line Voltage Module (NEMA 4 enclosure; 50A; for stove, dryer, etc.) | |

| 71052 | Low Voltage Module (NEMA 4 enclosure; for air conditioner) | |

| 071053 | Low Voltage Dual Module (NEMA 4 enclosure) | |

| 06154 | Remote System Status Panel – Hardwired | |

| 071056 | Symphony™ II Power Monitor |

http://www.CumminsPower.com/www/literature/technicalpapers/PT-9015-P1-Dissimilar-en.pdf

http://www.CumminsPower.com/www/literature/technicalpapers/PT-9016-P2-Dissimilar-en.pdf

http://www.CumminsPower.com/www/literature/technicalpapers/PT-9017-P3-Dissimilar-en.pdf

PDQIE, www.PDQIE.com, info@PDQIE.com, quote@PDQIE.com, Ryan@PDQIE.com, PDQ Industrial Electric, www.PDQIndustrialElectric.com, info@PDQIndustrialElectric.com, quote@PDQIndustrialElectric.com, Ryan@PDQIndustrialElectric.com are marketing tools of PDQ Electric Corp, a NJ Licensed Electrical Contractor. Reddy Kilowatt® is a Registered Trademark of Northern States Power Company. The information on this website is believed to be reliable, but we cannot guarantee that information will be accurate, complete and current at all times and should be reaffirmed by a licensed professional before relying on it. PDQIE will from time to time revise information, products and services described in-on this Website, and reserves the right to make such changes without notice. Use of this Website is entirely at your risk. Materials and information in this Website (including text, graphics, and functionality) are presented without express or implied warranties of any kind and are provided "as is". It is your responsibility to evaluate the accuracy, completeness and usefulness of any opinions, advice, services and information provided.