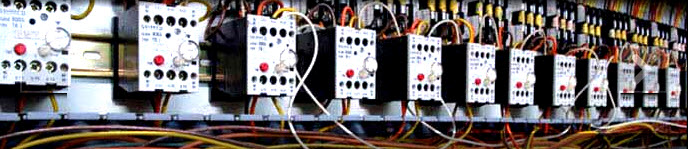

Industrial - Commercial

Industrial - Commercial  Electrical

Contractor

Electrical

Contractor

PDQ Electric Corp

NJ, PA, DE, MD, NY, CT, DC, MA, RI

|

PDQIE - PDQ Industrial ElectricAutomated Conveyor SystemsDesign - Installation - Maintenance - Repair

FLEXIBLE SCREW CONVEYERS A flexible screw conveyor, also known as a spiral conveyor, screw conveyor, helix conveyor or centerless auger conveyor, consists of a spring steel or stainless steel, flexible screw that is enclosed in a flexible or rigid plastic tube, or a rigid steel tube, and driven by an electric motor normally located at the discharge end of the conveyor. This simple design delivers efficient performance and high reliability while reducing maintenance and cost. When properly engineered according to the specific characteristics of the material being conveyed and the process into which it will be integrated, a flexible screw conveyor can outperform rigid screw conveyors, bucket elevators, drag chain conveyors, aero mechanical conveyors and other equipment intended to transport powder and bulk solid materials. The intake end of a flexible screw conveyor tube is typically equipped with a charging adapter a U-shaped trough that connects to the outlet of a hopper or directly to the outlet of process equipment such as a bulk bag discharger, bag dump station, grinder, crusher, screener, blender, reactor or storage vessel of any kind. The flexible screw passes through the charging adapter trough, exposing a section of the screw to material flowing into the trough from above. When rotating, the exposed section of screw feeds material into the outer tube, where it is then propelled through the tube by the enclosed portion of the screw. A phenomenon resulting from the loose fit of a rotating flexible screw within a tube filled with bulk material, is that the screw automatically self-centers within the tube, providing clearance between the screw and tube wall. This affords sufficient space for particles to flow without damage, depending on the fragility and size of particles being conveyed. A removable clean-out cap covers the intake end of the conveyor tube, permitting rapid emptying and flushing of the tube, as well as disassembly and wash-down of components. Because the intake end of the screw requires no bearing, and since the discharge end is coupled to the motor drive above and/or beyond the point at which material exits the discharge spout, material does not come in contact with seals or bearings. The flexible screw is therefore the only moving part contacting material. MOVE VIRTUALLY ANY BULK MATERIAL Free-flowing and non-free-flowing materials and blends Flexible screw conveyors offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders—both free-flowing and non-free-flowing—with no separation of blended products. For moist, sticky, friable or other difficult-to-handle materials that pack, cake, smear, plug or break apart ther are special design flexible screw conveyors. ONLY ONE MOVING PART The only part contacting material in a flexible screw conveyor is the rugged flexible screw which is driven by an electric motor. As it rotates, the screw propels material and self-centers within the conveyor tube, providing constant clearance between itself and the tube wall. This simple design does not require cables, chains, disks, internal bearings, and numerous moving parts found in bucket elevators, rigid augers, drag chains, and/or aeromechanical conveyors—parts that can add initial cost, require maintenance, wear out, breed contamination, and/or break down. CONVEY IN ANY DIRECTION Whereas many conveyors (such as rigid screw conveyor, bucket elevator, drag chain conveyor and aero mechanical conveyor designs) have limited angles of incline and/or straight-only conveying paths, Flexible screw conveyors can move material vertically, horizontally, or at any angle—over, under, or around obstructions, through small holes in walls, ceilings and floors. GENTLE PRODUCT HANDLING AND BLENDING Flexible screw conveyors can handle your products gently, because the flexible screw self-centers as it rotates. This can provide ample clearance between the screw and tube wall to prevent grinding, crushing, and other product damage. In addition, the gentle rolling action created by the screw prevents the separation of blends throughout the entire length of the conveyor. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(877) 737-4349 (Toll Free)

(877) PDQ-4-FIX (Toll

Free)

(856) 625-6969 (Text

Messaging)

PDQ ia an Acronym for "Pretty Damn Quick"

|

PDQIE, www.PDQIE.com, info@PDQIE.com, quote@PDQIE.com, Ryan@PDQIE.com, PDQ Industrial Electric, www.PDQIndustrialElectric.com, info@PDQIndustrialElectric.com, quote@PDQIndustrialElectric.com, Ryan@PDQIndustrialElectric.com are marketing tools of PDQ Electric Corp, a NJ Licensed Electrical Contractor. Reddy Kilowatt® is a Registered Trademark of Northern States Power Company. The information on this website is believed to be reliable, but we cannot guarantee that information will be accurate, complete and current at all times and should be reaffirmed by a licensed professional before relying on it. PDQIE will from time to time revise information, products and services described in-on this Website, and reserves the right to make such changes without notice. Use of this Website is entirely at your risk. Materials and information in this Website (including text, graphics, and functionality) are presented without express or implied warranties of any kind and are provided "as is". It is your responsibility to evaluate the accuracy, completeness and usefulness of any opinions, advice, services and information provided.