Industrial - Commercial

Industrial - Commercial  Electrical

Contractor

Electrical

Contractor

PDQ Electric Corp

NJ, PA, DE, MD, NY, CT, DC, MA, RI

|

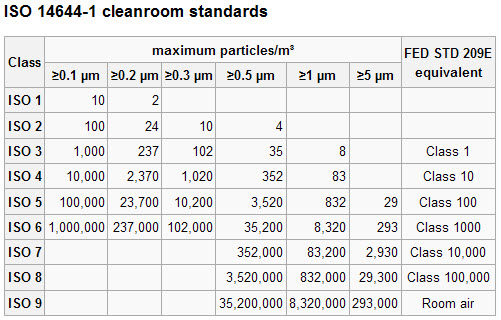

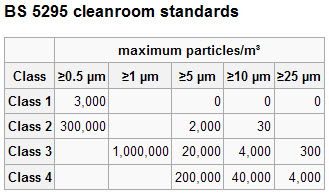

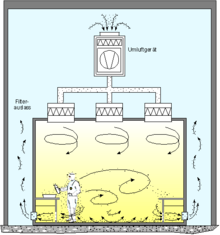

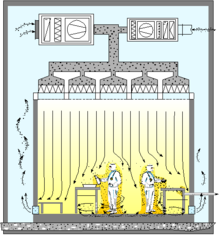

PDQIE - PDQ Industrial ElectricClean-Room EnvironmentA Clean-Room is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a Clean-Room has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter, 0.5 µm and larger in diameter, corresponding to an ISO 9 Clean-Room. OVERVIEW Clean-Rooms can be very large. Entire manufacturing facilities can be contained within a Clean-Room with factory floors covering thousands of square meters. They are used extensively in semiconductor manufacturing, biotechnology, the life sciences and other fields that are very sensitive to environmental contamination. The air entering a Clean-Room from outside is filtered to exclude dust, and the air inside is constantly recirculated through high efficiency particulate air (HEPA) and/or ultra low particulate air (ULPA) filters to remove internally generated contaminants. Staff enter and leave through airlocks (sometimes including an air shower stage), and wear protective clothing such as hats, face masks, gloves, boots and coveralls. Equipment inside the Clean-Room is designed to generate minimal air contamination. Even specialised mops and buckets exist. Clean-Room furniture is also designed to produce a minimum of particles and to be easy to clean. Common materials such as paper, pencils, and fabrics made from natural fibers are often excluded; however, alternatives are available. Clean-Rooms are not sterile (i.e., free of uncontrolled microbes)[1] and more attention is given to airborne particles. Particle levels are usually tested using a particle counter. Some Clean-Rooms are kept at a positive pressure so that if there are any leaks, air leaks out of the chamber instead of unfiltered air coming in. Some Clean-Room HVAC systems control the humidity to low levels, such that extra equipment ("ionizers") are necessary to prevent electrostatic discharge (ESD) problems. Low-level Clean-Rooms may only require special shoes, ones with completely smooth soles that do not track in dust or dirt. However, shoe bottoms must not create slipping hazards (safety always takes precedence). Entering a Clean-Room usually requires wearing a Clean-Room suit. In other Clean-Rooms, in which the standards of air contamination are less rigorous, the entrance to the Clean-Room may not have an air shower. There is an anteroom (known as a "gray room"), in which the special suits must be put on, but then a person can walk in directly to the room (as seen in the photograph on the right). Some manufacturing facilities do not use fully classified Clean-Rooms, but use some Clean-Room practices together to maintain their cleanliness requirements. Clean-Room Air Flow Principles Air flow pattern for "Turbulent Clean-Room"  Air flow pattern for "Laminar Flow Clean-Room" Clean-Rooms maintain particulate-free air through the use of either HEPA or ULPA filters employing laminar or turbulent air flow principles. Laminar, or unidirectional, air flow systems direct filtered air downward in a constant stream towards filters located on walls near the Clean-Room floor. Laminar air flow systems are typically employed across 80 percent of a Clean-Room ceiling to maintain constant air processing. Stainless steel or other non-shed materials are used to construct laminar air flow filters and hoods to prevent excess particles entering the air. Turbulent, or non-unidirectional, air flow uses both laminar air flow hoods and non-specific velocity filters to keep air in a Clean-Room in constant motion, although not all in the same direction. The rough air seeks to trap particles that may be in the air and drive them towards the floor, where they enter filters and leave the Clean-Room environment. CLEAN-ROOM CLASSIFICATIONS Clean-Rooms are classified according to the number and size of particles permitted per volume of air. Large numbers like "class 100" or "class 1000" refer to FED-STD-209E, and denote the number of particles of size 0.5 µm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. "class 2000". A discrete-particle-counting, light-scattering instrument is used to determine the concentration of airborne particles, equal to and larger than the specified sizes, at designated sampling locations. Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 Clean-Room has at most 105 = 100,000 particles per m³. Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. The table locations without entries are non-applicable combinations of particle sizes and cleanliness classes, and should not be read as zero. Because 1 m³ is approximately 35 ft³, the two standards are mostly equivalent when measuring 0.5 µm particles, although the testing standards differ. Ordinary room air is approximately class 1,000,000 or ISO 9. Clean-Room Clasification Standards | |

(877) 737-4349 (Toll Free)

(877) PDQ-4-FIX (Toll

Free)

(856) 625-6969 (Text

Messaging)

PDQ ia an Acronym for "Pretty Damn Quick"

|

PDQIE, www.PDQIE.com, info@PDQIE.com, quote@PDQIE.com, Ryan@PDQIE.com, PDQ Industrial Electric, www.PDQIndustrialElectric.com, info@PDQIndustrialElectric.com, quote@PDQIndustrialElectric.com, Ryan@PDQIndustrialElectric.com are marketing tools of PDQ Electric Corp, a NJ Licensed Electrical Contractor. Reddy Kilowatt® is a Registered Trademark of Northern States Power Company. The information on this website is believed to be reliable, but we cannot guarantee that information will be accurate, complete and current at all times and should be reaffirmed by a licensed professional before relying on it. PDQIE will from time to time revise information, products and services described in-on this Website, and reserves the right to make such changes without notice. Use of this Website is entirely at your risk. Materials and information in this Website (including text, graphics, and functionality) are presented without express or implied warranties of any kind and are provided "as is". It is your responsibility to evaluate the accuracy, completeness and usefulness of any opinions, advice, services and information provided.