PDQIE - PDQ Industrial Electric

Variable Frequency Drives (VFD)

Variable Speed Drives (VSD) Adjustable Speed Drives (ASD)

VFD APPLICATIONS INCLUDE

Pumps: Many types of pumps consume significantly

less electricity when their rotational speed is reduced. If demand varies or if reduced flow rates are required in

closed-loop systems, VFDs can optimize system operation and reduce electricity use.

Fan Motors: Ventilation and cooling fans are

usually designed for peak load conditions, which may occur only a few hours each year. By adjusting fan speed for

the required air volume, a VFD reduces electricity use while maintaining process conditions and comfort levels.

Cooling tower fans and combustion air fans are also good candidates for VFDs. Running a fan with a VFD at 50% flow

can reduce its electricity consumption by as much as 87%, depending on the application.

Conveyor Motors: Speed control and

Syncronization

Variable Speed Drive

Q&A

(Frequently Asked Questions)

Q What's the difference between a Non-regenerative DC

Drive and a Regenerative DC Drive?

A. The difference between these two types of DC drives

is:

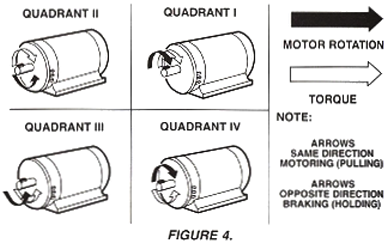

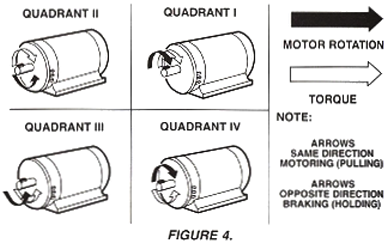

Nonregenerative DC

Drives - Nonregenerative DC drives are the most conventional type in common usage. In their

most basic form they are able to control motor speed and torque in one direction only as shown by Quadrant

I in Figure 4. The addition of an electromechanical (magnetic) armature reversing contactor or manual

switch (units rated 2 HP or less) permits reversing the controller output polarity and therefore the

direction of rotation of the motor armature as illustrated in Quadrant III. In both cases torque and

rotational direction are the same.

Regenerative DC Drives

- Regenerative adjustable speed drives, also known as four-quadrant drives, are capable of controlling not

only the speed and direction of motor rotation, but also the direction of motor torque. This is

illustrated in Figure 4.

The term regenerative describes the ability of the drive under

braking conditions to convert the mechanical energy of the motor and connected load into electrical energy

which is returned (or regenerated) to the AC power source.

When the drive is operating in Quadrants I and III, both motor

rotation and torque are in the same direction and it functions as a conventional nonregenerative unit. The

unique characteristics of a regenerative drive are apparent only in Quadrants II and IV. In these

quadrants, the motor torque opposes the direction of motor rotation which provides a controlled braking or

retarding force. A high performance regenerative drive, is able to switch rapidly from motoring to braking

modes while simultaneously controlling the direction of motor rotation.

A regenerative DC drive is essentially two coordinated DC drives

integrated within a common package. One drive operates in Quadrants I and IV, the other operates in

Quadrants II and III. Sophisticated electronic control circuits provide interlocking between the two

opposing drive sections for reliable control of the direction of motor torque and/or direction of

rotation.

Q What's the difference between a variable frequency

drive (VFD) and a variable speed drive (VSD)?

A A variable frequency drive (VFD) refers to AC drives only and a

variable speed drive (VSD) refers to either AC Drives or DC Drives. A VFD varies the speed of an AC motor by

varying the frequency to the motor. A VSD, referring to DC motors, changes the speed by varying the voltage to

the motor.

Q What is the difference between a VSD and a Soft

Start Starter?

A The difference is the speed that the motor can run, when at full

speed. With a soft start starter, the motor is reduced voltage started, and then when the motor is at full speed,

or a timing circuit has timed out, a "running by-pass contactor" pulls in and the motor continues to run at full

base speed. With a VSD (Variable Speed Drive) or VFD (Variable Frequency Drive) (these are the same thing, just

different names for the same unit), The motor will soft start, and you can vary the speed of the motor, by varying

the output frequency from the VSD or VFD. If you do not need to vary the speed of the motor, once the motor is up

to speed, then the correct solution is a soft start starter for that motor. If the process requires the motor speed

to vary at anytime, the correct solution is a VSD-VFD. The cost for a soft start starter is much less than a VSD or

VFD.

Q Can a variable frequency drive replace a

softstart?

A Yes, a variable frequency drive can replace a soft start starter,

since most drives give you a current limiting ramp to start and stop your motor. BUT, if you do not need to vary

the production speed of your motor, then the soft start starter is still the correct product for the application.

This is because the cost of the soft start starter is less than the cost of a variable frequency drive.

Q Are the variable frequency drives phase

sensitive?

A No, variable frequency drives are not phase sensitive. You can

adjust the direction of rotation of the motor, through the software of the drive.

Q Can a variable frequency drive be used for a fan

application, blower application or a pump application?

A This is one of the best applications for an AC drive. In most

fan-pump applications, there is a need to vary the output of the fan-pump. This is very easy to achieve with an AC

drive and you get the benefit of reduced energy cost of running the motor.

Q How can a Variable Speed Drive improve our

production?

A A drive can be "tuned" to your application to achieve maximum

output of the equipment.

Q Can I run a 230V, 3Ph motor with 230V, 1Ph

input?

A Yes, you run most 230V, 3Ph motors with only 230V, 1Phase input!

Call PDQIE.

Q Can I convert my DC Drive application to an AC

Drive?

A Yes, You can convert your DC drive system; to an AC drive system by

replacing both the motor and the drive. Consideration must be given for the torque and speed range of the DC motor,

when converting to AC. You will need to consider using a "Vector" AC drive for this conversion.

Q Will a variable frequency drive or variable speed

drive save me money?

A Yes, the AC drive can save you money on operating cost, when the

load and motor speed can be varied. By reducing the speed of the motor, you will consume less energy, which will

reduce your electric bill.

|  Industrial - Commercial

Industrial - Commercial  Electrical

Contractor

Electrical

Contractor