Industrial - Commercial

Industrial - Commercial  Electrical

Contractor

Electrical

Contractor

PDQ Electric Corp

NJ, PA, DE, MD, NY, CT, DC, MA, RI

|

PDQIE - PDQ Industrial ElectricRadio Frequency Identification Detection (RFID)RFID

Evolution: Common and not so common uses for

RFID: What you

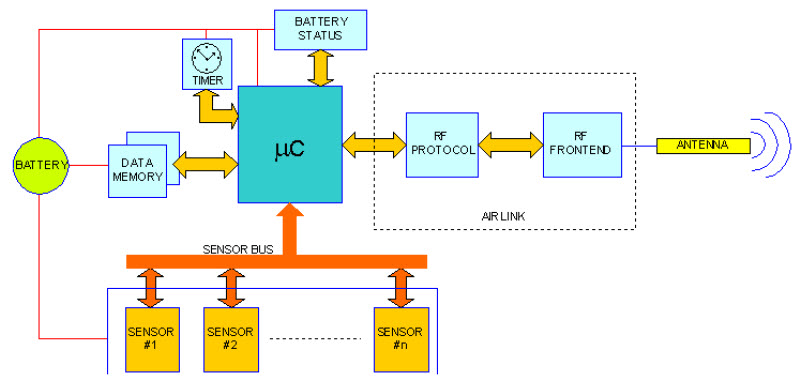

probably DID NOT know about RFIDs: The omnipresent barcode labels that triggered a revolution in identification systems are being found to be inadequate in an increasing number of cases. The integration of sensors (especially the silicon based ones) into semi-passive RFID tags has recently generated a lot of interest among the RFID community. Only the silicon can meet the aggressive cost performance requirements of most new applications. Silicon based sensors are also benefiting from vast resources developed for the mainstream electronics: microprocessors, memories, and advanced linear microcircuits. The advantage of using Silicon Sensor Technology is not only in increased price-performance ratio, but also in an incredible volume manufacturing capability that IC manufacturing brings. Generic Sensor Tag Logic

Diagram

| |

(877) 737-4349 (Toll Free)

(877) PDQ-4-FIX (Toll

Free)

(856) 625-6969 (Text

Messaging)

PDQ ia an Acronym for "Pretty Damn Quick"

|

PDQIE, www.PDQIE.com, info@PDQIE.com, quote@PDQIE.com, Ryan@PDQIE.com, PDQ Industrial Electric, www.PDQIndustrialElectric.com, info@PDQIndustrialElectric.com, quote@PDQIndustrialElectric.com, Ryan@PDQIndustrialElectric.com are marketing tools of PDQ Electric Corp, a NJ Licensed Electrical Contractor. Reddy Kilowatt® is a Registered Trademark of Northern States Power Company. The information on this website is believed to be reliable, but we cannot guarantee that information will be accurate, complete and current at all times and should be reaffirmed by a licensed professional before relying on it. PDQIE will from time to time revise information, products and services described in-on this Website, and reserves the right to make such changes without notice. Use of this Website is entirely at your risk. Materials and information in this Website (including text, graphics, and functionality) are presented without express or implied warranties of any kind and are provided "as is". It is your responsibility to evaluate the accuracy, completeness and usefulness of any opinions, advice, services and information provided.